The background and beginnings of the project

JLAKit is a new hydro-electric turbine concept and is the fruit of collaboration between hydro-electric equipment manufacturer JLA Hydro SPRL and CODÉART, a Belgian non-profit making NGO.

JLAKit combines :

- the considerable experience of Willot JLA workshops in the construction of Banki turbines (since 1988).

- the experience of CODÉART in technology transfer to the countries of the developing world (also since 1988).

August 2002: a revelation in the heart of Africa

A mission was organised in the Democratic Republic of Congo on behalf of Codéart. The objective: to draw up an inventory of the possibilities for small hydro-energy sources in the surroundings of Butembo.

We discovered that craftsmen were making small cross-flow turbines with the most basic of resources, often from scrap. Choosing the easiest way to build these turbines often proves to be detrimental to the correct geometry of the machine, to its performances and reliability, but nevertheless, these machines worked somehow and the craftsmen in this sector are highly motivated!

We came to the conclusion that the best solution to help these craftsmen would be to provide them with quality raw materials so that they could build, using basic technical resources, reliable and high-performance turbines, for specifically intended fields of use.

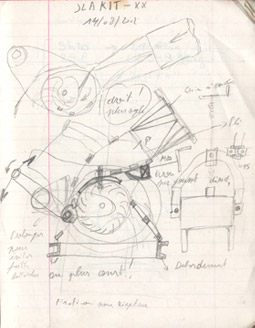

After a bad night’s sleep looking for a break from the heat, too strong a dose of coffee and an interminable wait in a busy airport, the first sketch of the JLAKit saw the light of day, with the central idea of improving locally built machines whilst remaining at their level.

2004: After the revelation, time for thinking

Codéart asked us to look further into the issue. The design of the first JLAKit became a completion of engineering study course dissertation, supervised by Codéart.

The aim was to study the design of a machine that met with the low-cost demand for power supply of less than 30 kW and mainly designed for driving small mills and other facilities.

All that remained was to find a student with knowledge in engineering design, engineering drawing, an interest for the field of hydro-energy, availability to work in the workshop, etc. Samuel Treinen, from the Institut Supérieur Gramme (Gramme higher education institute) was chosen by Codéart.

2005: Construction of an initial prototype

He produced excellent work, enabling the construction, in 2005, of an initial prototype. Via various testing, this contributed to the validation of the machine’s hydraulic profile and helped to give a clear definition of its characteristics: specific speed, specific capacity, efficiency curve, etc.

However, the machine produced was costly: slightly too advanced, its structure was too complicated. A simplified version was therefore studied to reduce costs, without harming performance and the proven reliability of the first prototype.

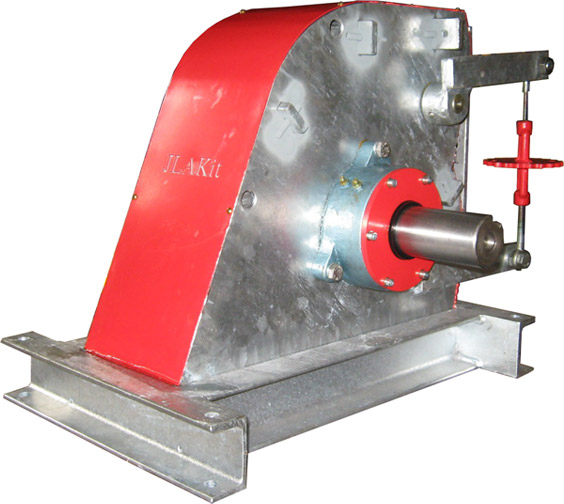

Some elements were completely redesigned and we improved the structure to split it into two main sections: the injector and the rotor mounting.

The last version of the JLAKit, version 3, includes several minor modifications made to simplify assembly of the turbine.

2010 : The JLA KIT today